Bremnes Seashore is recognized for the fantastic quality of the SALMA products. This is due to increased fish welfare in the waiting tanks and to the gentle handling of the raw material.

Ensuring good water quality control thru regularly checking the oxygen saturation and temperature secures that the salmon will recover faster after being pumped from the wellboat.

When using waiting tanks, the wellboat pumps the fish into the waiting tanks, and can then leave the harbor. This means that the wellboat does not have to stay in the harbor until the slaughterhouse has received all fish. At the same time you avoid the use of waiting cages in the sea, and this also leads to increased control and biomass security.

The fish welfare you achieve through i.a. correct temperature before slaughtering, and subsequent filleting of the fish before it is in rigor mortis, gives a super fresh product.

“SALMA” is today one of the world`s most famous brands within the seafood industry. This due to technology from MMC First Process and scientists from Bremnes Seashore. MMC First Process mission is to make our customers the best in the world in regards of handling, processing and cooling of the sea`s most important food resources in an effectively, sustainably and carefully manner.

Our customers can, by use of waiting tanks, be assured that this is the most sustainable way to handle and make the best raw material for round fish and filleting.

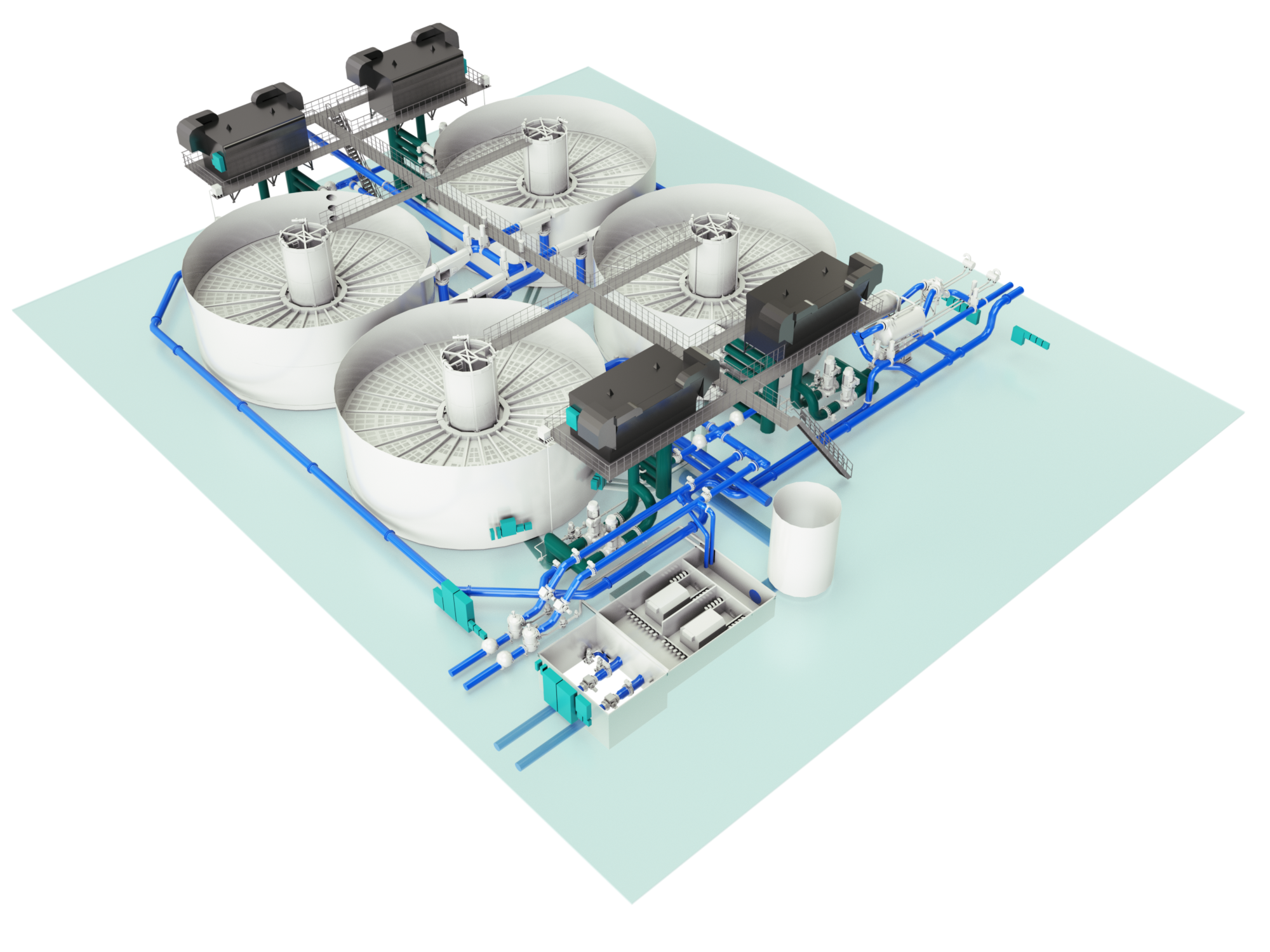

Australis, which is one of the major producers of salmon in Chile, chose 4 waiting tanks of a total of 4,000 cubic meters from MMC First Process. This is almost the same system as delivered to Bremnes Seashore.

System solutions for sustainable fish handling from MMC First Process delivers the quality the market and responsible suppliers prefer.