References from our customers worldwide

The first value-added plant for the pelagic industry –

This will be the first Pelagic Transformation Plant built specifically for value added products, where MMC First Process is the turnkey provider.

“Donegal Fish invited tenders from technology companies all over Europe, but it became clear relatively early in the process that they would continue to work with MMC First Process. The solution that we have designed includes a system for filleting, pinboning and packing consumer portions, as well as an industrial vacuum-packing installation and temperature control system for mackerel fillets.

Authentic, personal, knowledgeable and driving has been the philosophy and values that Br Sperre has lived up to since the company started in the 1930s.

In their strive to live up to these values, they have always recognized the importance of modern facilities and modern production equipment.

In August 2020 MMC First Process has delivered the largest modernization of their facilities in the company`s history. In September the same year, a modern “state of the art” processing plant was fully operative and handling the season´s catch.

This modern processing plant is prepared for round frozen mackerel, herring, caplin and other pelagic species.

The design criteria have through the whole process been biomass security, efficiency and product quality. MMC First Process is proud to present a complete system solution for sustainable fish handling.

Lerøy Havfisk primary design criterion is based on supreme fish quality. Lerøy Havfisk is engaged in building vessels in Norway to preserve and strengthen the unique competence regarding construction and production of fishing vessels.

MMC First Process is a Norwegian supplier with long traditions regarding sustainable fish handling. We know what is required to satisfy the demands of quality, and are proud to have delivered a state-of-the-art factory onboard MS Kongsfjord. The vessel has just completed its first trip with excellent reports. The fish factory have delivered supreme quality with quantities above 80 tons per day.

MMC First Process is recognized as a complete system supplier of integrated solutions for handling and processing of fish, rest materials and silage. Our products are built to last, with supreme quality optimized for seamless operations in the toughest conditions on the planet.

The intention of the new design was to increase cost- and production efficiency, as well as fish quality in a sustainable operation.

The vessel is a combined HG and shrimp trawler, designed with innovative solutions for transportation of biomass, thanks to the newly developed RID pump technology delivered by MMC First Process. The pumping system increases efficiency and biomass security.

MMC First Process – Sustainable fish handling – It´s in our nature.

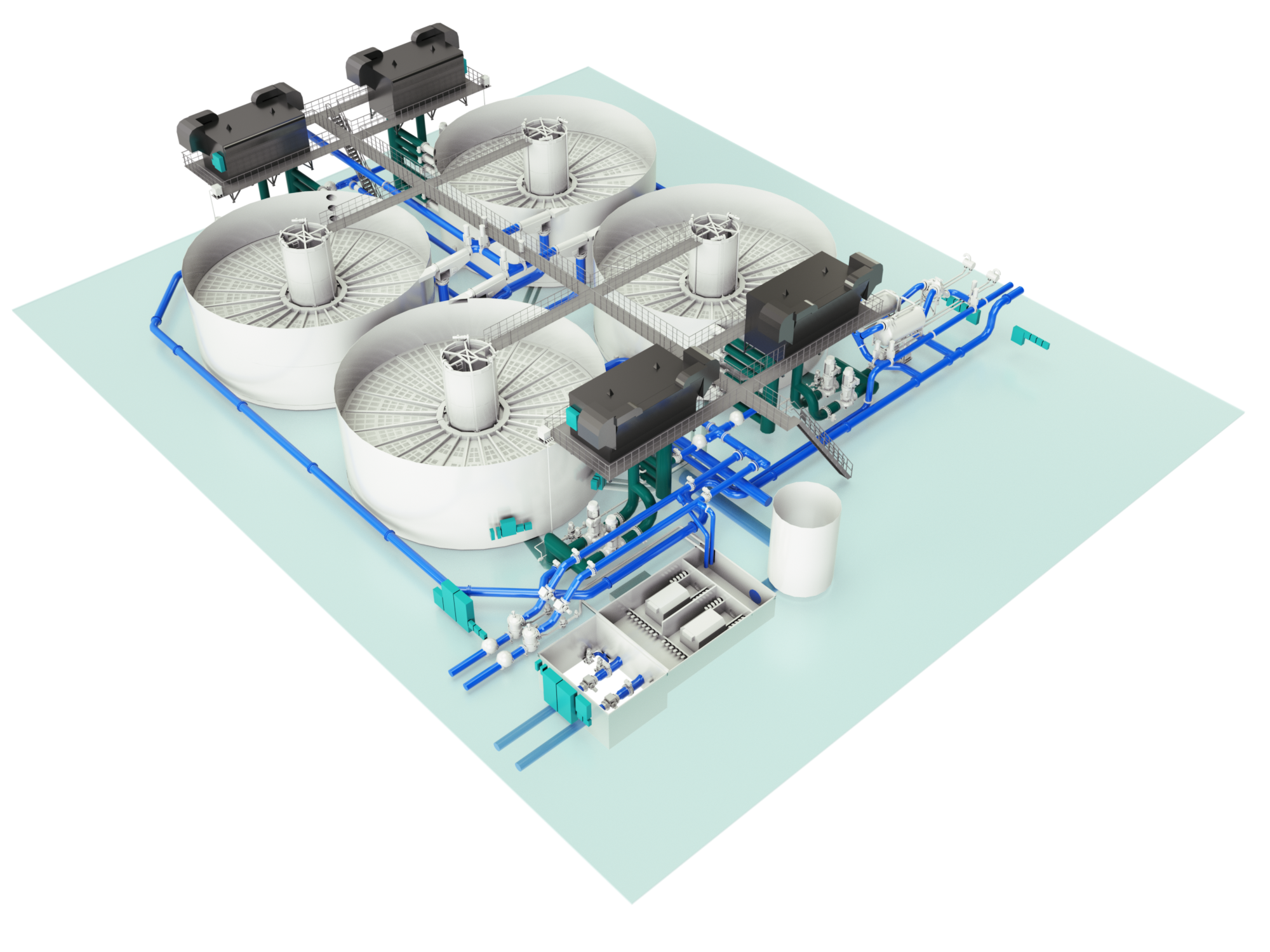

Bremnes Seashore is recognized for the fantastic quality of the SALMA products. This is due to increased fish welfare in the waiting tanks and to the gentle handling of the raw material.

Ensuring good water quality control thru regularly checking the oxygen saturation and temperature secures that the salmon will recover faster after being pumped from the wellboat.

When using waiting tanks, the wellboat pumps the fish into the waiting tanks, and can then leave the harbor. This means that the wellboat does not have to stay in the harbor until the slaughterhouse has received all fish. At the same time you avoid the use of waiting cages in the sea, and this also leads to increased control and biomass security.

The fish welfare you achieve through i.a. correct temperature before slaughtering, and subsequent filleting of the fish before it is in rigor mortis, gives a super fresh product.

“SALMA” is today one of the world`s most famous brands within the seafood industry. This due to technology from MMC First Process and scientists from Bremnes Seashore. MMC First Process mission is to make our customers the best in the world in regards of handling, processing and cooling of the sea`s most important food resources in an effectively, sustainably and carefully manner.

Our customers can, by use of waiting tanks, be assured that this is the most sustainable way to handle and make the best raw material for round fish and filleting.

Australis, which is one of the major producers of salmon in Chile, chose 4 waiting tanks of a total of 4,000 cubic meters from MMC First Process. This is almost the same system as delivered to Bremnes Seashore.

System solutions for sustainable fish handling from MMC First Process delivers the quality the market and responsible suppliers prefer.

MMC First Process have years of experience in supplying complete systems for wellboats.

Together with our long lasting and trusted customer Sølvtrans, we are proud to receive positive feedbacks from fish farmers about meeting their highest fish welfare requirements. Ronja Storm even set an unofficial world record of 729 tons of Atlantic Salmon, the customer claims.

With 7450m3 of fish hold volume, Ronja Storm was by far the biggest wellboat when she was delivered in 2019. The vessel is equipped with a complete system solution for fish handling and fish welfare and water quality monitoring system from MMC First Process.

Our main focus is design and implementing turn key solutions for fish handling. Water quality systems from MMC First Process provide fish welfare, biomass security and quality.

The vessel is designed for loading and unloading by under- and over-pressure, securing smooth transition of fish between tanks without any mechanical pumping. Straining the water off and making the vessels water supply a single source, resulting in zero water pollution. Every drop of water from the huge fish holds are filtered before UV-treatment to clean the water before pumping it back to the sea.

MMC First Process looks forward to follow this grand lady for service and maintenance during many productive years on the coast of Tasmania.